PRECISION MOTORSPORT FABRICATION

At Concept Racing we specialise in bespoke fabrications

We manufacture a wide range of high quality components for the motorsport industry from drawing, pattern, photograph or even a cardboard box mock up. We also work on cars brought “in house”. We will have a go a most things and are often contacted to help solve problems or make parts that people are struggling to replace. Below are some examples of our work & expertise. There are many more examples in the Galleries on our website. We specialise in one offs & small batch runs and aim to provide a friendly & reliable service. We also provide a range of off the shelf products through our Online Shop.

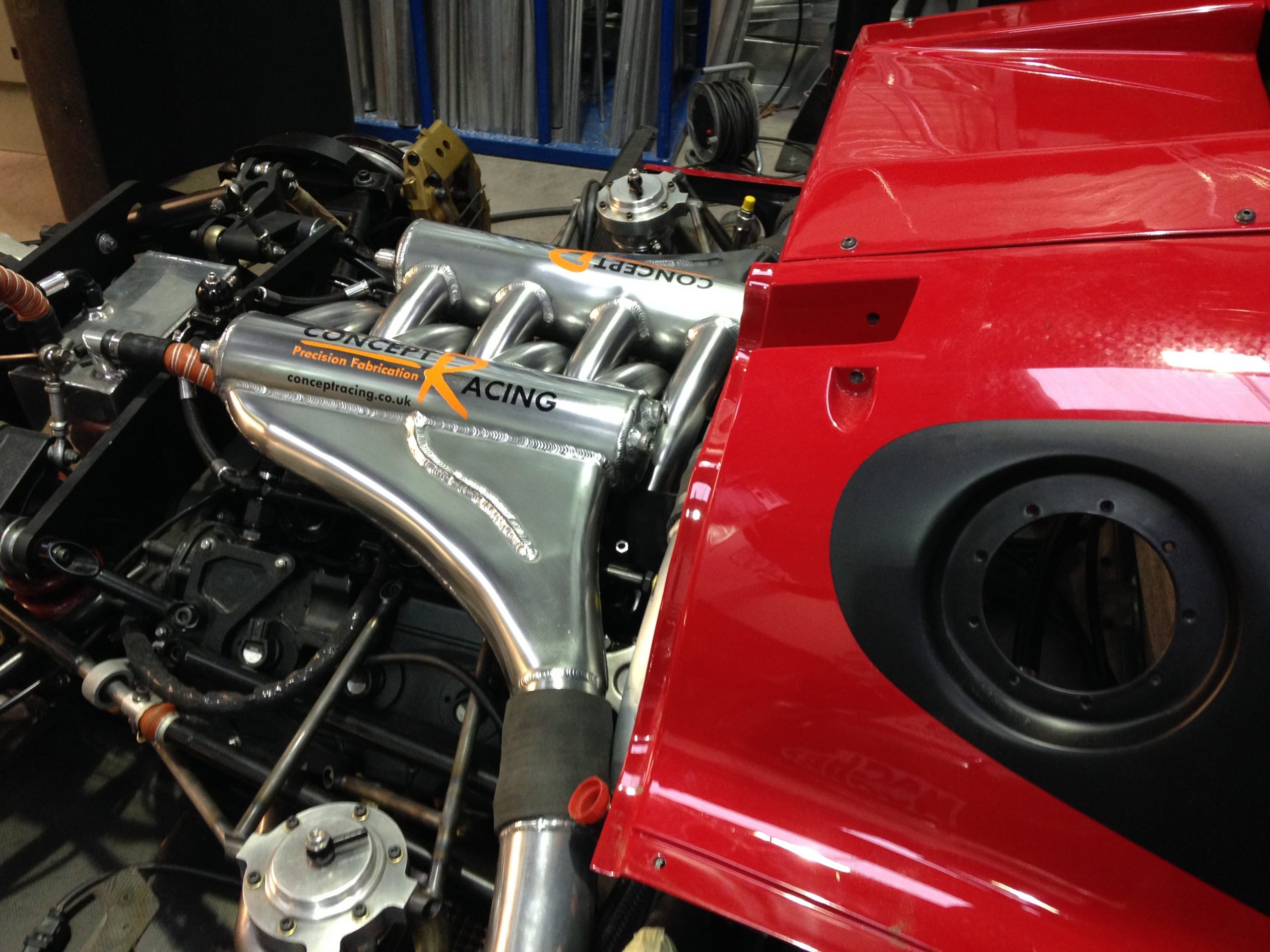

CHARGE COOLERS, INTERCOOLERS & PLENUMS

Bespoke charge coolers, intercoolers and plenums manufactured at Concept Racing. We use efficient, lightweight aluminium cores Read More…

FUEL TANKS & SWIRL POTS

Competition, foam filled fuel tanks & swirl pots manufactured to customer specifications or as replicas of original tanks. Aluminium bag tank replacements Read More…

DRY SUMP TANKS, OIL CATCH TANKS & OIL COOLERS

Concept Racing dry sump tanks are a high quality aluminium construction with an internal baffle system to prevent oil surge, starvation Read More…

RADIATORS, HEADER TANKS & WATER SWIRL POTS

Maintaining optimum temperature is crucial for a race engine’s performance. We can make aluminium radiators from your drawing Read More…

BESPOKE FUEL, AIR, OIL & WATER SYSTEMS

At Concept Racing we offer an in house design, manufacture and fitting service for full air, oil and water installations Read More

REPAIRS & MANUFACTURE

Maintaining optimum temperature is crucial for a race engine’s performance. We can make aluminium radiators from your drawing Read More…

MAGNESIUM, ALUMINIUM & TITANIUM

Specialist welding services carried out in house please contact us to discuss Read More…

Online Shop

All products can be manufactured with different fittings or dimensions to suit your requirements.

We ship WORLDWIDE.

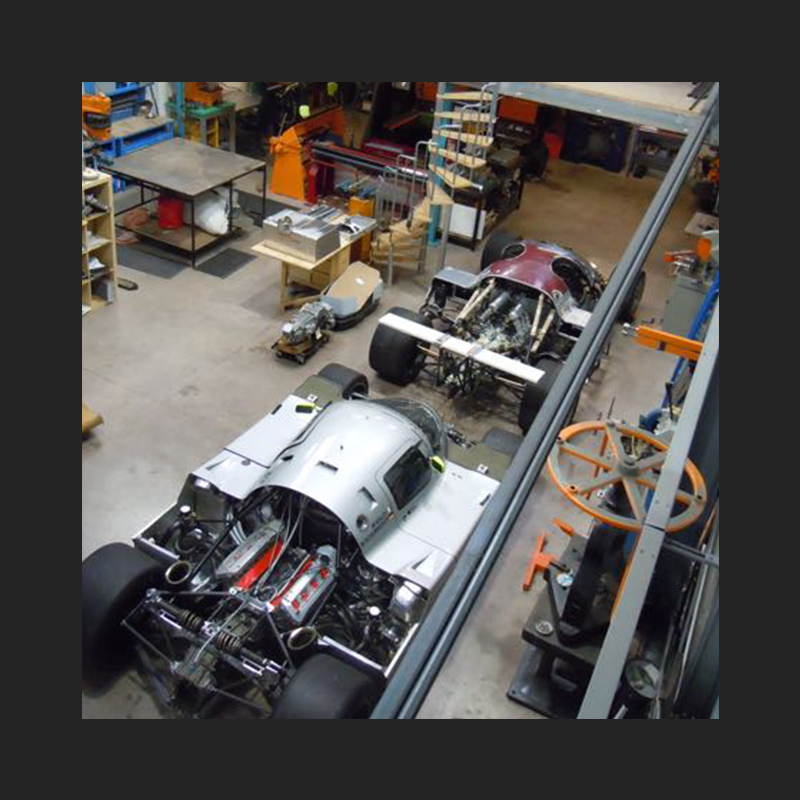

Galleries

We manufacture a wide range of parts from pattern, drawing, photograph and cardboard box mock up as well as working on cars brought “in house”. We will have a go a most things and are often contacted to help solve problems or make parts that people are struggling to replace.