Concept Racing Vortex

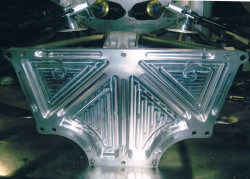

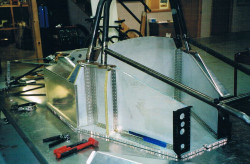

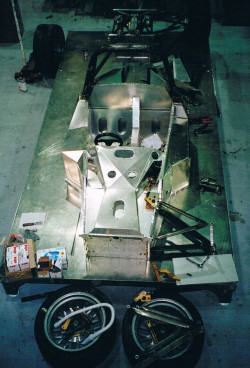

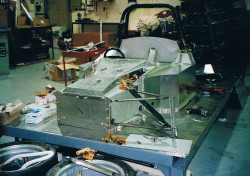

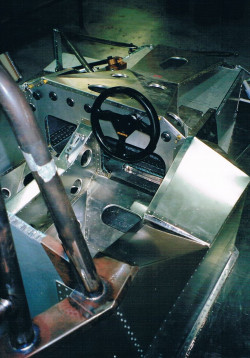

The carbon bodywork used on this car was made by Reynard for their 2KQ Le Mans LMP900 sports prototype. The body is a fully autoclaved carbon fibre unit over a Nomex core and is super stiff and very light. The Floors, rear diffuser and side pods are all carbon as is the twin element rear wing and wing posts. The chassis was designed and made by Concept Racing and is made from aluminium honeycomb. The engine is a supercharged Hyabusa upgraded in order to make it strong enough to cope with the 350bhp available. The super charger is a Rotrex unit which is a mechanical turbo running a gearbox internally to step the revs up 10 to 1. With the current gearing it runs at 14psi but can run up to 22psi if required. It also runs its own sealed oil system and oil cooler.

The engine oil system is cooled by a water cooled oil cooler and the induction charge is cooled by both an intercooler and a charge cooler (water cooled inter-cooler). All water radiators and intercoolers have shaped header tanks to improve flow and have also been made at Concept Racing. The wishbones are a Cromoly aero section design also made by Concept racing.

Take a look at our Concept Racing Vortex project. We specialise in bespoke motor sport racing fabrications.

We manufacture a wide range of high quality components for the motorsport industry from drawing, pattern, photograph or even a cardboard box mock up. We also work on cars brought “in house”. We will have a go a most things and are often contacted to help solve problems or make parts that people are struggling to replace. Below are some examples of our work & expertise. There are many more examples in the Galleries on our website. We specialise in one offs & small batch runs and aim to provide a friendly & reliable service. We also provide a range of off the shelf products through our Online Shop.

Bob Hall began his career making aluminium bodywork and plumbing solutions for historic sports cars. Over the last 25 he has worked on some of the most prestigious race cars ever built, from Maserati 250Fs, Lotus Grand Prix cars, Rolls Royce and Aston Martin to current Formula 1 engined hill climb cars and 24 hour Le Mans cars. Over this period of time he has gained vast experience in a multitude of areas within the Motorsport Industry. Bob has an unparalleled attention to detail combined a passion for creation and skilled craftsmanship.

Clare Daniels joined the Concept Team in 2006 and is involved in all aspects of the business. Clare is a skilled fabricator who has been at Bob’s side for the last 24 years. Over this time Clare has gained an in depth knowledge of dry sump tank manufacture and design, high performance aluminium heat exchangers and fuel tanks. Clare is the main point of contact at Concept and will do everything possible to provide you with a friendly, knowledgeable and reliable service.

Follow us on Instagram.

Concept Racing Vortex